Item No. | UNIT | |

Nominal Pore Size | Pore Size | 7.4 Angstroms 2.2 Angstroms |

Hardness Number | N | ≥90 |

Equilibrium Water Capacity | % | ≤20 |

Silver Content | % | ≥40 |

Flammability | Non-flammable | |

Binder | 20% |

PRODUCTS DESCRIPTION

Silver Exchanged Zeolite Description

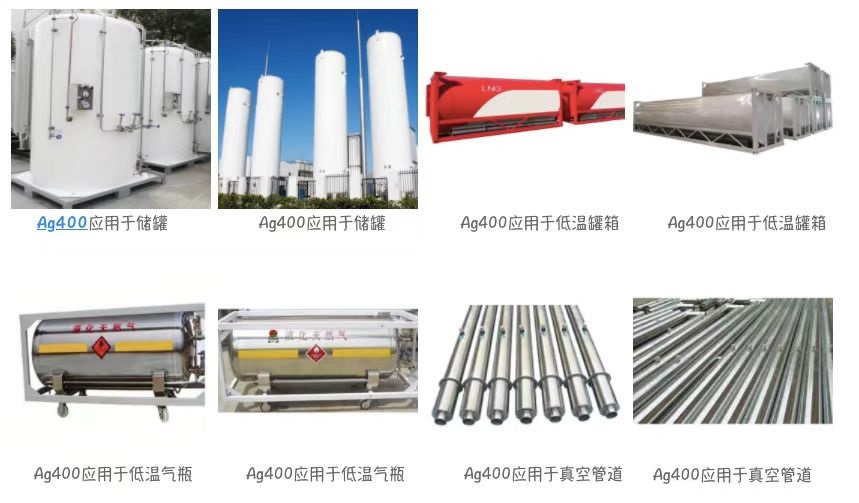

Ag400 silver molecular sieve is a new generation of high-efficiency hydrogen absorbing material used in the vacuum interlayer of high-vacuum multi-layer insulation containers. It can effectively adsorb the slowly released H2 of carbon steel, stainless steel, insulation materials, etc., so as to ensure that the interlayer always maintains super High vacuum.

Item No. | UNIT | |

Product name | Type | Standard level |

Nominal Pore Size | Pore Size | 7.4 Angstroms 2.2 Angstroms |

Hardness Number | N | ≥90 |

Granularity(1.8-2.4MM) | % | ≥90 |

Heat Absorption | BTU/lb. H2O | 1800 |

Equilibrium Water Capacity | % | ≤20 |

Silver Content | % | ≥40 |

Flammability | Non-flammable | |

Binder | 20% | |

Apparent Density | g/cm3 | 0.91 – 1.10 |

Moisture | % | <2.0 |

Ag400 Molecular SieveSpecification

Nominal Pore Size : 7.4 Angstroms into large cavities, 2.2 Angstroms into B cage

Hardness Number : 90 minimum

Heat Absorption : 1800 BTU/lb. H2O

Equilibrium Water Capacity : 20% by weight

Silver Content : 37% minimum

Flammability : Non-flammable

Thermal Stability : Efficient adsorption up to 500 degree C

Binder : Acid- resistant type, 20% by weight

Apparent Density : 0.91 – 1.10 g/cm3

Moisture : <2.0%

SILVER CONTAINING MOLECULAR SIEVES Feature

Ag400 is a synthetic silver-exchanged zeolite for gettering hydrogen from vacuum spaces of cryogenic apparatus, selective removal of halogens from gas streams and as a hydrogen/oxygen recombined catalyst. This inorganic alumina silicate material contains supercharges within its crystalline structure which are especially large and uniform in size. These cavities and their large entrances (pores) allow extremely large capacity for trapping contaminants and maximum utilisation of the exchanged silver cations

PRIMARY APPLICATION AREAS:

Hydrogen Getter For Vacuum with a cryogenic tank vacuum space

Why We Focus On Hydrogen Getter With A Cryogenic Tank Vacuum Space

To maintain good thermal insulation performance, the vacuum degree of the dissection is generally below 10-2Pa Pa. The leakage and outgassing in the high-vacuum dissection insulation tank are the main factors that destroy its vacuum degree.

Leakage: leakage of the inner and outer tank. The main components are N2、O2 、CO2 and H2O, which account for 20% to 30% of the leaked gas and can be easily absorbed by activated carbon or traditional zeolites at 77 K or above.

Outgassing: outgassing of carbon steel, stainless steel, aluminum foil, and cellophane, producing mainly H2, H2 accounts for 70%~80% of the leakage and outgassing and it is difficult to be absorbed, making it a key factor for the destroy of vacuum degree.

The Main Characteristics Of The Ag400 Series Are As Follows:

The high-vacuum multi-layer insulation tank is mainly composed of the outer shell (carbon steel), inner tank (stainless steel), reflective material (aluminum foil), and insulation material (cellophane).

a) the adsorption capacity of PdO for H2 is about 8 times that of Ag400. In practical use, taking into account the influence of other factors, in order to ensure the same hydrogen adsorption performance, the recommended amount of Ag400 is 10-15 times that of PdO;

b) the adsorption capacity of Ag400 is higher than that of imported and domestic products;

c)Application of hydrogen getter in high-vacuum multi-layer insulation tank plays a key role in maintaining the vacuum degree for a long period. The maintenance of vacuum degree mainly depends on the characteristics and amount of the hydrogen getter, and whether it can work well.

Export To Europea Cryogenic Vaccum Lonex Type Ag400 Silver Exchanged Zeolite Ag84 Na2 Al86 Si106 O384 Molecular Sieve

Export To Europea Cryogenic Vaccum Lonex Type Ag400 Silver Exchanged Zeolite Ag84 Na2 Al86 Si106 O384 Molecular Sieve NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap