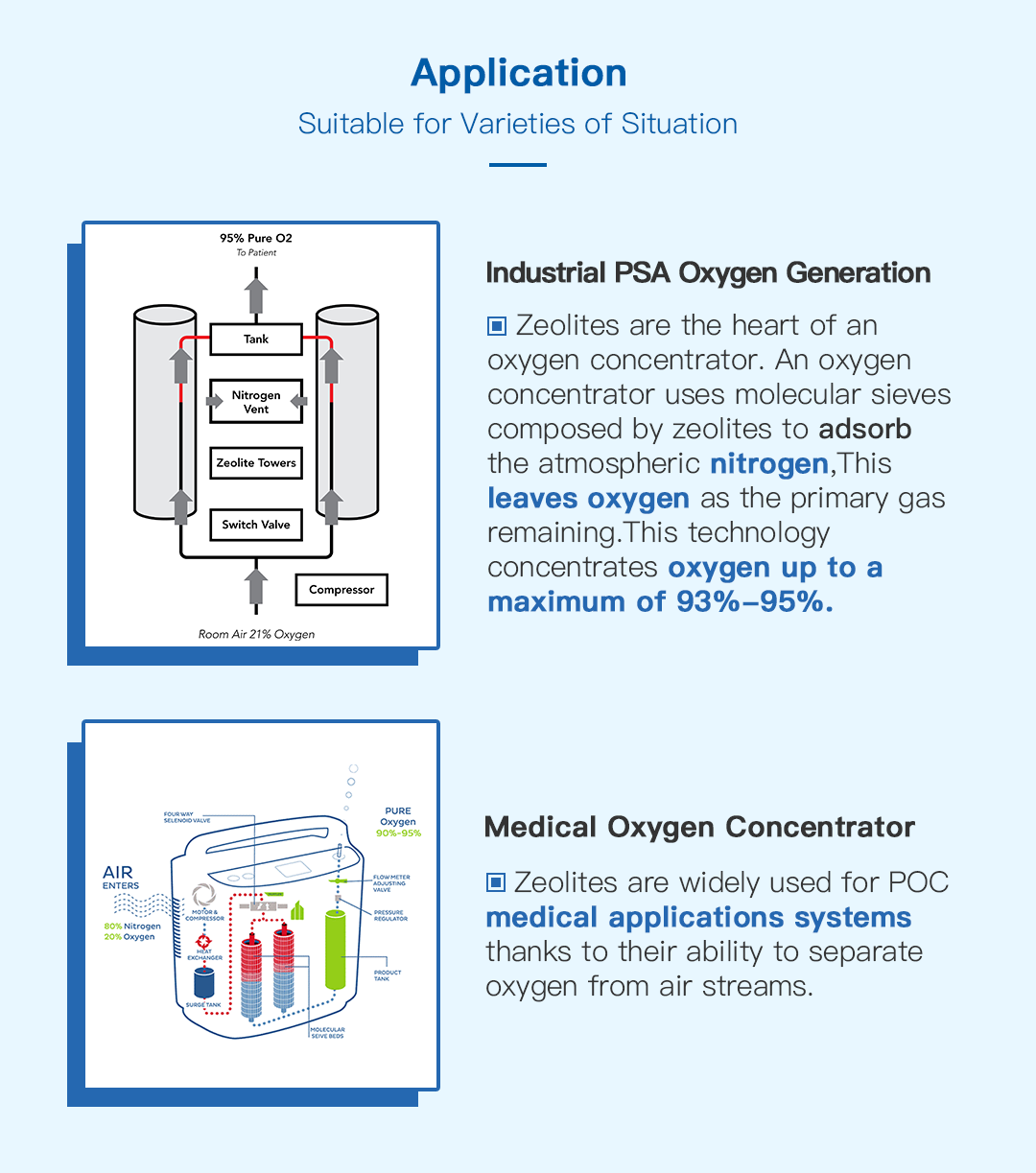

Zeolite-Sodium oxygen enrichment molecular sieve are new X type molecular sieve specialized in PSA oxygen generator plant for oxygen producing with high N2 adsorption capacity and N2/O2selectivity.Sodium oxygen grade molecular sieve are mainly used in PSA oxygen generator for generation of high purity oxygen with the advantages of faster adsorption rate, higher oxygen production rate and longer use life. They are the substitute of 5A (CaA) type molecular sieve. Normally,Sodium molsieve is designed for portable oxygen generator 1-5L/Min, Sodium molsieve is designed for industrial oxygen plant, oxygen purity is up to 93%±3%.

PRODUCTS DESCRIPTION

1. Sodium oxygen grade molecular sieve can replace 13X-APG in old cryogenic air separation unit without

changing equipment design

2. Smaller column with Sodium oxygen grade molecular sieve can reach the same air processing capacity

3. Enlarging air processing capacity when using same amount of 13X-APG

4. Energy Saving: For it can help extending adsorption column transfer time

from general 4h to 6h (min), transfer time reduced from regular 6 times/d to 4

times/d, saving great amount of energy especially in electrical heating system

5. Strengthen the equipment stability for reduced transfer time

6. Facilitating examine and repair the equipment without equipment stopping

work

7. Increase the molecular sieve life span for reduced regenerative time

factory 13X High purity oxygen concentration zeolite molecular sieve Sodium

Molecular sieve is a kind of uniform microporous, mainly composed of silicon, aluminum, oxygen and some other metal cation adsorbent or film material, the pore size and general molecular size, according to its effective pore size to screen a variety of fluid molecules. Zeolite molecular sieve refers to those with the role of molecular sieve natural and artificial crystalline silicon aluminate. Zeolite molecular sieve due to its unique structure and performance, has become an independent discipline, the application of zeolite molecular sieve has been throughout the petrochemical industry, environmental protection, biological engineering, food industry, medicine and chemical industry and other fields. With the development of various industries in the national economy, the application prospect of zeolite molecular sieve is increasingly broad.

Hand & Storage Recommendation

Molecular Sieve should be handled to avoid generation of dusty conditions at the workplace. Storage in a dry warehouse is recommended. Open packages should be resealed to prevent contamination and adsorption of water or other gases and vapors. The material in bag-in-box should be used within 12 months,while bag-in-steel drum should be used within 24 months.

Package of lithium & Sodium molecular sieve:

25kg & 125kg / steel drum. palletized with plastic film for lithium molecular sieve

Packaging & Shipping

1. Packaging Details:25KG net woven bag with inner plastic bag. 50KG net in Cardboard Drum. and other packing.You can also choose according to your requirements

2.Delivery Detail:We always provide sea transportation and air transportation.We can also provide according to your requirements.

3.Delivery time:Because of the nature of our products,we always delivery in 21 days.

Regeneration

To achieve good operating performance and long life as much as possible, after a certain period of time use must be regenerated .After correct molecular sieve regeneration , make it get the low attenuation of mechanical properties and adsorption

There are two basic approaches:

Temperature variation .

Generally used in the preheating gas heating, purge molecular sieve to about 200℃, and stripping down the adsorbate .

Variable pressure .

Usually used in the gas phase adsorption process.Maintain a constant temperature adsorbent and by reducing pressure and backing purge inert gas , to remove the adsorbate.

"Note:This is normal specification, in case of a particular application, application, please contact us by email at info@fznewmaterials.com for technical information."

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap