If you have any questions about our products, please question submitted to us, we will be the first time to answer your questions!

How to process zsm5?

Propylene is a very essential building block in the petrochemical industry. There is a fast growing in its demand that is steadily expanding its market. Fluid catalytic cracking units is the second largest propylene source for petrochemical application. FCC units are primarily used in the production of gasoline. However, refiners have taken advantage with the aim of producing and recovering large amounts of propylene from their Fluid catalytic cracking unit by raising the severity of reaction through riser temperature, installation of a propylene recovery unit and addition of a catalyst that is shape selectivity.

ZSM-5 is nowadays used as a very efficient fluid catalytic cracking additive for increasing light olefins production i.e. propylene. This short review will be exclusively focused on ZSM-5-containing additives and look at the main strategies used in the design and modifications of ZSM-5 catalysts to increase the propylene production in the FCC units. The review will highlight the most important and the recent modification methods used in enhancing ZSM-5 performance in the FCC process to maximize the yield of light olefins in general, and in particular that of propylene.

These methods include particle size and acidity modification, phosphorus treatment, mesoporous/hierarchical structure creation, incorporation alkali metals and some selected transition metals and introduction of rare-earth metal.

What's main effective of FEIZHOU Attapulgite?

FEIZHOU Attapulgite is added into painting and coatings for rheological control.It can effectively prevent sedimentation and delamination of pigments, improve the weatherability and scratch resistance of coatings, and improve the bonding strength between coatings and substrates.

1. In wall coatings, FEIZHOU Attapulgite helps to prevent the paint from flowing down and to improve the smoothness of the wall surface. What’s more,it can greatly improve the scratch resistance and aging time of the exterior wall coating, and also the bonding strength between the coating film and the wall, the hardness of the coating film and the surface self-cleaning ability

2. When FEIZHOU Attapulgite is adsorbed by powder coatings, movable layer is formed on its surface.It improves flowing property by preventing powder coatings from absorbing moisture and agglomerating.

3. The main function of FEIZHOU Attapulgitein floor paint is to improve its ability of weather resistance, scratch resistance and leveling performance.

What’s Chemical principal of thickening and thixotropy property of FEIZHOU Attapulgite

The thickening and thixotropy property of FEIZHOU Attapulgite is mainly related to its unique structure. FEIZHOU Attapulgite is light grey powder.

But in microscopic state, FEIZHOU Attapulgite is electrically charged rod-shaped particles -like mesh structure. The cross needle structure forms mesh structure thus results in good thickening performance.

The force of mesh structure and the physical adsorption force are relatively weak, when shear thinning is applied, this network is easy to break,viscosity decreases; when shear thinning is removed, network is restored,viscosity increases, thixotropic property shows.

How to gain thickening and thixotropic property?

When thickening and thixotropic agent is added into your product, thickening and thixotropy property is gained FEIZHOU Attapulgite is one of the most common used agents for this purpose. Except from the good behavior in thickening and thixotropy property, FEIZHOU Attapulgite has other special properties. That’s the reason why FEIZHOU Attapulgite is the preferred choice for a lot of applications, including coatings application.

What’s thickening and thixotropic property?

Thickening means the increase in viscosity;Thixotropy is closely related with shear thinning. Shear thinning means that the viscosity of a liquid changes in relation to shear stress - it is dependent on the force acting on the coating film. At high levels of shear stress, lower viscosity is observed. This viscosity increases when the shear stress is reduced. The effect of a liquid increasing in viscosity as the duration of shear exposure increase, while the shear intensity remains constant, is referred to as thixotropy.

How about Molecular Sieve Application in Gas Dehydration and Purification?

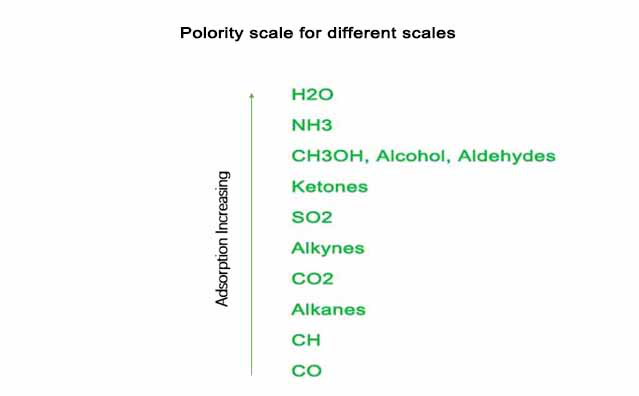

Zeolite molecular sieve is a aluminosiliate with uniform pores. These pore diameters are similar in size to small molecules. Thus molecules with diameter less than the pore size can enter molecular sieve and be adsorbed, while molecules with diameter bigger than the pore size can not go into molecular sieve and be excluded (Tab. 1). Moreover, molecular sieve pore size can be precisely adjusted through introducing of different metal ions such as Na+(4A, 13X), K+(3A), Ca+(5A, CaX), Li+(LiLSX, LiLX). This property enables molecular sieve to separate molecules of different size. Another important property of molecular sieve is it is easier to adsorb polar molecules other than non polar molecules, thus makes it possible to separate molecules by its polarity (Fig. 1).

Tab.1 pore size of different kinds of molecules

| Molecules | Critical Diameter in Å |

| Helium | 2 |

| Hydrogen, Acetylene | 2.4 |

| Water, O2, Monoxide and Dioxide | 2.8 |

| Nitrogen | 3 |

| Ammonia, Hydrogen Sulphide | 3.6 |

| Argon | 3.8 |

| Methane | 4 |

| Ethylene, Ethylene monoxide | 4.2 |

| Ethane, Methanol, Ethanol | 4.4 |

| Methyl-mercaptan | 4.5 |

| Propane, nC4 to nC22 | 4.9 |

| Propynene | 5 |

| Ethyl-RH, Butene 1, Butene 2 trans | 5.1 |

| Difluochloromethane (R22) | 5.3 |

| ISO C22 | 5.6 |

| Cyclohexane | 6.1 |

| Toluene, Paraxylene | 6.7 |

| Benzene | 6.8 |

| Carbon tetrachloride | 6.9 |

| Metaxylene | 7.1 |

| Tri-ethylamine | 8.4 |

Molecular Sieve Application

| Type | Pore Size | Application |

| 3A | 3Å | 1. Drying of unsaturated hydrocarbons 2. Cracked gas drying 3.Drying of natural gas, if COS minimization is essential, or a minimum co-adsorption of hydrocarbons is required 4. Drying of highly polar compounds, such as methanol and ethanol |

| 4A | 4Å | 1. Drying and removing of CO2 from natural gas, LPG, air, inert and atmospheric gases, etc 2. Removal of hydrocarbons, ammonia and methanol from gas streams (ammonia syn gas treating) 3. Dehydration of refrigerant and air in the air break units of buses, trucks and locomotives 4. Packed in small bags for packing desiccant for foods, etc |

| 5A | 5Å | 1. The strong ionic forces of the divalent calcium ion makes it an excellent adsorbent to remove water, CO2, H2S from sour natural gas streams, while decreasing COS formation. It can also adsorbs light mercaptans. 2. It is also used for the separation of normal- and iso-paraffins 3. Production of high purity N2, O2, H2 and inert gases from mixed gas streams 4. PSA hydrogen purification |

| 13X | 10Å | 1. Removal of CO2 and moisture from air (air pre-purification) and other gases 2. Separation of enriched oxygen from air 3. Removal of mercaptans and hydrpogen sulphide from hydrocarbon liquid streams such as LPG, butane, propane etc 4. Catalyst protection, removal of oxygenates from hydrocarbons (olefin streams) 5. Removal of n-chained compositions from aromatics |

| 13X-1 | 10Å | 1. with smaller beads is degined for small medical oxygen concentrator 2. 13X-1 is desinged for bigger industrial or medical oxygen concentrators smaller than 200 Nm3/h |

| 13X-2 | 10Å | 1. 13X-2 with smaller beads is degined for small medical oxygen concentrator; 2. JLOX-102, JLOX-103 is desinged for bigger industrial or medical oxygen concentrators larger than 200 Nm3/h |

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: