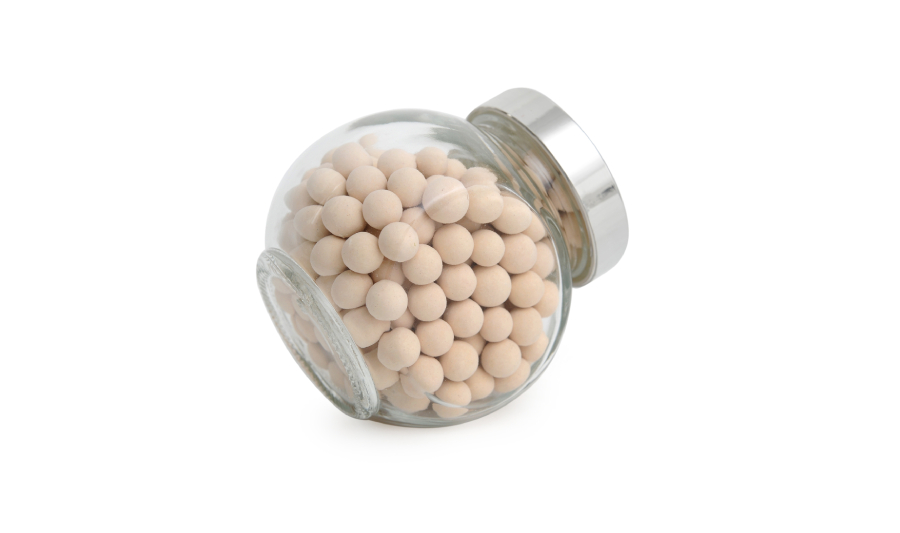

Molecular Sieve 3A EDG

Molecular sieve 3A EDG is specially designed for ethanol dehydration by PSA or VSA unit. It has outstanding water adsorption capacity, little ethanol co-adsorption, high mechanical strength, low attrition.

PRODUCTS DESCRIPTION

Production Description

3A EDG Molecular Sieve is specification designed for dehydrating fuel grade ethanol, as traditional distillation of ethanol is only possible up to the azeotropic point at 95.6% volume. The preferred technology for the dehydration of ethanol to get anhydrous and fuel grade ethanol is pressure swing adsorption using 3A EDG molecular sieves. 3A EDG molecular sieve selectively adsorbs the water from the solution to produce anhydrous ethanol with less than 1% volume. This is the dehydrating process of choice for fuel ethanol product. Molecular sieve 3A EDG for ethanol dehydration not only have good water adsorption capacity, but also should adsorb methanol and ethanol as little as possible. 3A EDG uses special process to achieve this purporse. It has outstanding water adsorption capacity, little ethanol co-adsorption, high mechanical strength, low attrition. At the same time, the by-product can be greatly supressed.

| Property | Unit | Beads |

| Diameter | mesh | 4x8 |

| Bulk Density | g/cm3 | ≥0.64 |

| Crush Strength | N | ≥70 |

| Loss on Attrition | % | ≤0.3 |

| CO2 Adsorption | % | ≤1.0 |

| Ethanol Delta T | ℃ | ≤1.8 |

| Methanol Delta T | ℃ | ≤10 |

| Water Adsorption Capacity | % | ≥20.5 |

| Loss on Ignition | % | ≤1.5 |

More Details:

1. Synonym: Ethanol Zeolite 3A, Ethanol Molsive 3A, Alcohol dehydration 3A

2. Typical Chemical Formula: 0.4K2O.0.6Na2O.Al2O3.2.OSiO2.4,5H2O

3. CAS NO.: 1318-02-1

4. Silica-alumina ratio: SiO2/ Al2O3≈2

Application:

1. Zeolite molecular sieve 3A EDG is used for anhydrosus and fuel grade ethanol or alcohol dehydraiton by PSA (pressure swing adsortpion method)

Stroage:

Keep 3A EDG Molecular Sieve in an air tight container until ready for use to avoid unintended moisture adsorption.

Regeneration&Activation:

3A EDG molecular sieve can be regenerated or activated either thermal regeneration method(Thermal Swing Adsorption, TSA); To remove moisture from a 3A molecular sieve, a temperature of 200-230℃ (390-570°F)is required. Molecular sieve 3A can also be regnerated or activated by lowering the pressure in the case of pressure swing processes (PSA). A properly regenerated or activated molecular sieve can give moisture dew points below -100℃. The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.

"Note:This is normal specification, in case of a particular application, application, please contact us by email at info@fznewmaterials.com for technical information."

China 13X Zeolite Molecular Sieve Desiccant Price 1.7-2.5mm Adsorbent To Eliminate Sulfur Odor From Liquefied Petroleum Gas (LPG)

China 13X Zeolite Molecular Sieve Desiccant Price 1.7-2.5mm Adsorbent To Eliminate Sulfur Odor From Liquefied Petroleum Gas (LPG) NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap