Item No. | UNIT | |

Product name | Type | Standard level |

Diameter | 20-50mesh | (0.4-0.8mm) |

N2 Absorption Capacity | (ml/g) | ≥22.00 |

N2/O2 Selectivity | ≥6.2 | |

Bulk Density | (g/ml) | 0.63±0.03 |

PRODUCTS DESCRIPTION

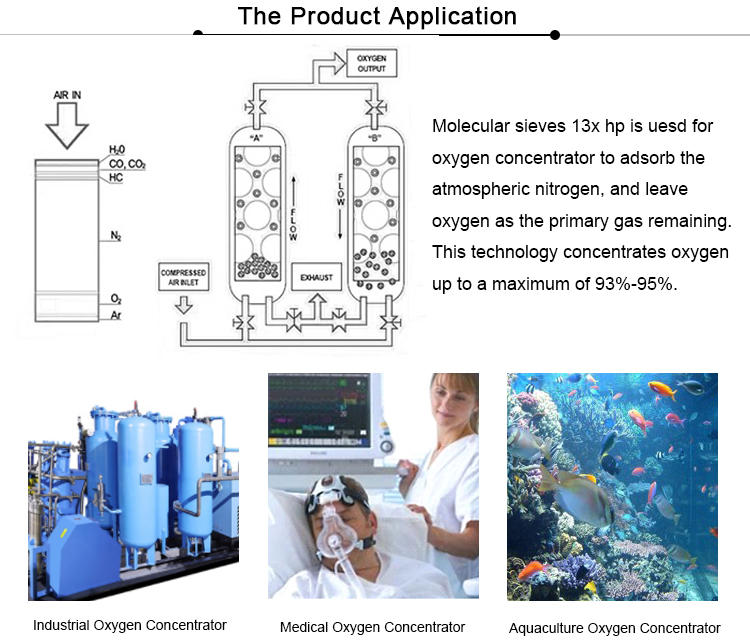

Medical oxygen purification typically involves separating oxygen from other atmospheric gases, primarily nitrogen, using methods like cryogenic distillation or pressure swing adsorption (PSA). These methods ensure the oxygen meets the purity standards required for medical use, which is generally 99.5% or higher for oxygen produced via cryogenic distillation. PSA concentrators, commonly used for home oxygen therapy, typically produce oxygen with 90-95% purity.

Molecular Sieve 13XHP in the form of beads and pellets provides a great way in purifying the oxygen with the help of PSA oxygen generation process. Such type of product to get high level of pure oxygen to enhance the performance of healthcare operations is known as an oxygen generator.

High performance zeolite-based molecular sieves adsorbents, which are used to adsorb and remove nitrogen in the ambient air with a high efficiency PSA process to produce an oxygen flow at 95.5 % of concentration.Series Molecular sieves for oxygen concentrators

Lithium molecular sieves are highly effective for oxygen enrichment in both medical and industrial applications due to their ability to selectively adsorb nitrogen from the air, allowing for the production of oxygen-enriched air. They are commonly used in pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA) oxygen concentrators.

How they work:

Selective Adsorption:

Lithium molecular sieves, specifically lithium X-type zeolites, are designed to preferentially adsorb nitrogen over oxygen.

PSA/VPSA Process:

In PSA and VPSA systems, air is passed through a bed of lithium molecular sieves.

Nitrogen Removal:

The sieves adsorb the nitrogen, while the oxygen passes through, resulting in an oxygen-enriched stream.

Desorption:

When the sieve bed is depressurized (PSA) or a vacuum is applied (VPSA), the adsorbed nitrogen is released, allowing the sieve to be regenerated for further use.

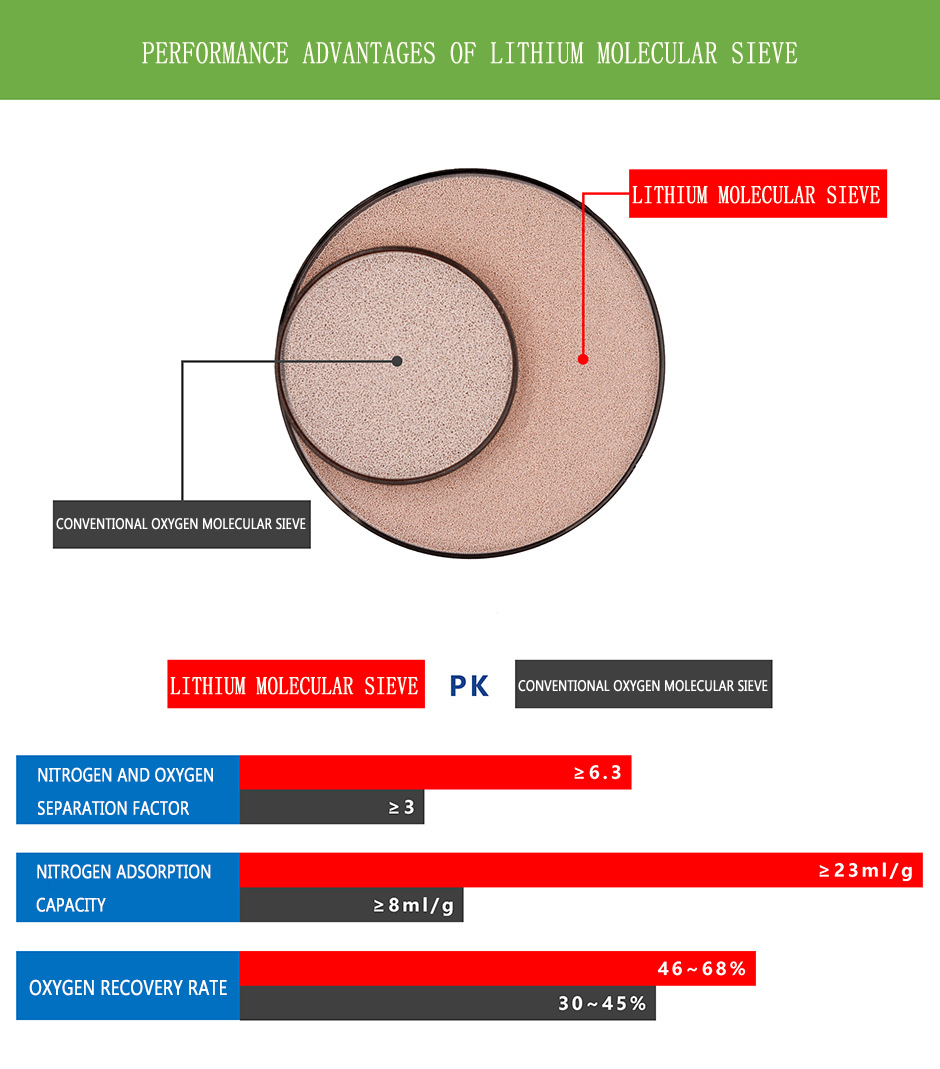

Advantages of Lithium Molecular Sieves:

High Nitrogen Adsorption Capacity:

They can adsorb significantly more nitrogen than other molecular sieves, like sodium-based ones.

Excellent N2/O2 Selectivity:

They effectively separate nitrogen from oxygen, leading to higher oxygen purity.

Durability and Longevity:

They offer good wear resistance and long service life, reducing maintenance and replacement costs.

Compact Design:

Their efficiency allows for the creation of smaller, more portable oxygen concentrators.

Lithium Zeolite Applications:

Medical Oxygen Concentrators: They are used in both small, home-based units and larger hospital concentrators.

Industrial Oxygen Production: They play a vital role in VPSA plants for large-scale oxygen production.

Other Applications: They can be used in ozone production, aquaculture, and wastewater treatment, where oxygen enrichment is beneficial.

Key Features Of Lithium Molecular Sieves

High Purity Oxygen: Lithium molecular sieves enable the production of oxygen with high purity (typically around 93% +/- 3%).

Efficiency: They improve the efficiency of oxygen generation, leading to lower energy consumption and reduced operating costs.

Reliability: Their robust design ensures stable and reliable oxygen production.

Zeolite Desiccant Molecular Sieve 5A Hydrogen Purification Column Drying And Purification Of Natural Gas CO2 Adsorption

Zeolite Desiccant Molecular Sieve 5A Hydrogen Purification Column Drying And Purification Of Natural Gas CO2 Adsorption  3-10L Medical Oxygen 95-98% Purity Li Molecular Sieve LIX Zeolite 13X Lithium Molecular Sieve For Oxygen Concentrator Oxygen Concentrator Molecular Sieve

3-10L Medical Oxygen 95-98% Purity Li Molecular Sieve LIX Zeolite 13X Lithium Molecular Sieve For Oxygen Concentrator Oxygen Concentrator Molecular Sieve NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap