The heat of compression (HOC) type regenerative Dryer with molecular sieve is a twin tower type Dryer with molecular sieve as previously discussed with the primary distinction that the heat required for the regeneration process is taken from the compressor. This process utilizes the heat of compression, thus the naming convention. Some caution must be incorporated into the thought process of utilizing any of these design types. Obviously, the compressor must have the capacity to continuously offer the heat needed for regeneration. In situations where the compressor is running at part load or unloaded, inadequate heat levels could be experienced. If this event occurs there is not enough heat from the compression process to regenerate the offline tower resulting in elevated dew points downstream. While these units can be incorporated into both 2 stage oil free rotary screw compressors as well as centrifugal compressors, the more reliable of these applications are with the 2 stage rotary screw type as the heat levels are typically higher than with a 3 stage centrifugal compressor.

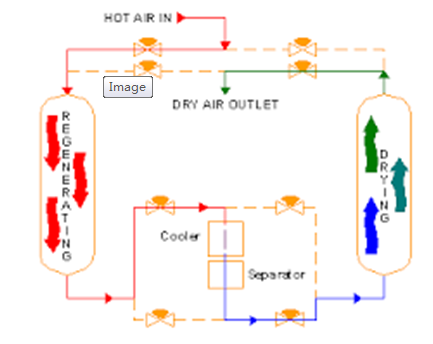

The primary design of the HOC Dryer with molecular sieve directs all the discharged air from the compressor to the HOC Dryer with molecular sieve . When using an HOC Dryer with molecular sieve , the compressor after-cooler is not used. Remember, we need the high temperature air for regeneration. This hot air is first directed to the offline tower or tower that needs regeneration. The hot air at this point is not saturated with water because of the elevated temperature (350 degree F). The air migrates through the offline tower picking up the moisture that is in the desiccant bed from it’s previous work cycle. The air is then directed to an after-cooler where the air is cooled to 100 degrees F and then to a separator to remove the condensed moisture. All of the air is then directed to the online or working bed where it is dried and then exits the Dryer with molecular sieve to the plant for use.

A second type of design termed “Inter-stage Heat of Compression Dryer with molecular sieve ” is used on centrifugal compressors by some manufacturers, continues to utilize the compressor after-cooler, cooling the air to 100 degrees F and directing this air to the online or working desiccant bed. A portion of air is taken from the the discharge of the 2nd stage of the compressor where the air is still at elevated temperatures. This air is directed to the offline tower to be used for regeneration where it sweeps the moisture from the bed and the air is then directed to the intercooler downstream of the 2nd stage of compression from where it was taken and prior to the inlet of the 3rd stage. The air passes through the intercooler and into the 3rd stage of compression where it is then compressed to its final pressure and continues the normal flow path through the after-cooler and into the working (online) Dryer with molecular sieve tower.

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap