More Details:

1. Synonym: Zeolite 4A, Molsive 4A, Zeolith 4A, 4A molecular sieve, 4 angstroms sieve

2. Typical Chemical Formula: Na2O.Al2O3.2SiO2.4,5H2O

3. CAS NO.: 1318-02-1

4. Silica-alumina ratio: SiO2/ Al2O3б≈2

PRODUCTS DESCRIPTION

Product Description

Molecular Sieve 4A is made from zeolite powder 4A (>70%) and binder. Zeolite powder 4A is generated by reaction of water, sodium hydroxide, sodium silicate and sodium aluminate. Molecular sieve 4A is usually used for in packaging of drugs, electronic components.Since 4A molecular sieve is more easier to be produced than 3A molecular sieve, 5A molecular sieve, 13X molecular sieve, it is more economic than other three desiccant. Molecular Sieve 4A have the shape of beads, pallets.

Application:

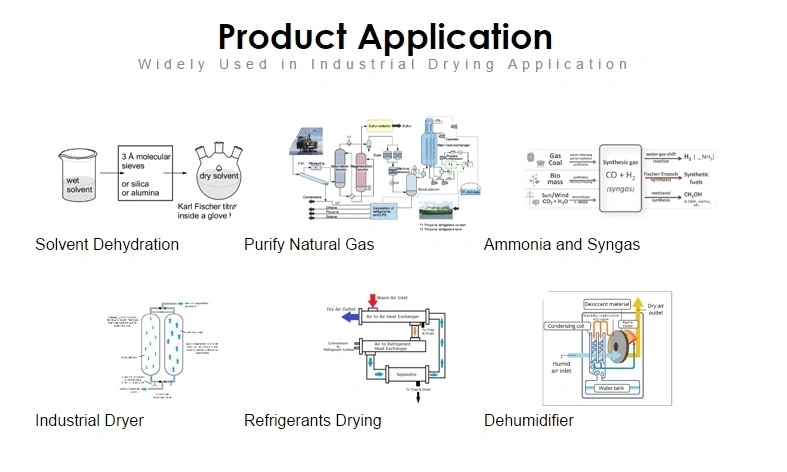

1. Molecular sieve 4A can be used for drying and removing of CO2 from natural gas, LPG, air, etc.

2. Molecular sieve 4A can be used for removal of hydrocarbons, ammonia and methanol from gas streams (ammonia syn gas treating)

3. Molecular sieve 4A can be used in dehydration of refrigerant and air in the air break units of buses, trucks and locomotives

4. Molecular sieve 4A can be packed in small bags for packing desiccant for foods, electronics elements, drugs etc

Storage:

Keep 4A Molecular Sieve in an air tight container until ready for use to avoid unintended moisture adsorption.

Regeneration&Activation:

Molecular sieve 4A can be regenerated or activated either thermal regeneration method(Thermal Swing Adsorption, TSA); To remove moisture from a 4A molecular sieve, a temperature of 200-230°C (390-570°F)is required. Molecular sieve 4A can also be regnerated or activated by lowering the pressure in the case of pressure swing processes (PSA). A properly regenerated or activated molecular sieve can give moisture dew points below -100°C. The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.

**The above information is for customers’ reference only. Performance characteristics vary depending on specific application. please contact us by email at info@fznewmaterials.com if detailed application method for materials needed.

High adsorption zeolite sphere molecular sieve 4A as small desiccant packets to protect pharmaceuticals and food For Drying Of CO2 From Natural Gas, LPG, Air, Inert And Athmospheric Gases

High adsorption zeolite sphere molecular sieve 4A as small desiccant packets to protect pharmaceuticals and food For Drying Of CO2 From Natural Gas, LPG, Air, Inert And Athmospheric Gases NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap