The Lithium Molecular Sieve has a fast oxygen extraction rate and high adsorption efficiency, but it is susceptible to moisture.

The lithium molecular sieve is commonly used on the market, so it is recommended that the oxygen generator should be kept ventilated and dry and be turned on regularly to avoid the molecular sieve being wet and causing the oxygen concentration to fall below the medical standard.

It is best to regularly use third-party testing equipment to test, the machine is not necessarily accurate.

LiLsx Molecular Sieve is just a raw material, and the core of determining oxygen concentration is filling technology.

How much the Oxygen Concentrator Molecular Sieve is filled and hermeticity determines the ability of continuous oxygen supply. If the filling technology is not tight and the friction is too large, it will cause moisture easily. After 1-2 years of machine use, the oxygen concentration drops rapidly.

For example, some oxygen concentrator machines of manufacturers do not have a low oxygen concentration alarm function, which is difficult for ordinary consumers to find.

Molecular sieve filling technology and mixing ratio are the core technologies.As mentioned earlier, the conversion efficiency of the American sodium sieve is not as good as that of the lithium sieve, and it has high moisture resistance and stability; the French lithium sieve has a fast oxygen output and high adsorption efficiency, but it is easy to get wet.

Molecular sieves act as the “heart” of industrial oxygen generators, and their maintenance directly affects the equipment’s production efficiency and safety. Over time, molecular sieves may face common issues such as decreased adsorption capacity, clogging, aging, and the accumulation of impurities, all of which can result in lower oxygen output, equipment failure, and disruptions in production. Regularly inspecting, cleaning, drying, and replacing the molecular sieve can extend its service life, improve operational efficiency, prevent production line downtime, and reduce high repair costs.

Maintenance Methods for Molecular Sieves in Industrial Oxygen Generators

Regular Inspections

Regular inspections form the foundation of effective molecular sieve maintenance. Enterprises should establish a comprehensive inspection system to ensure any potential issues are identified early during operation. Inspection items include:

Physical condition of the molecular sieve: Look for visible cracks or damage to the sieve’s surface.

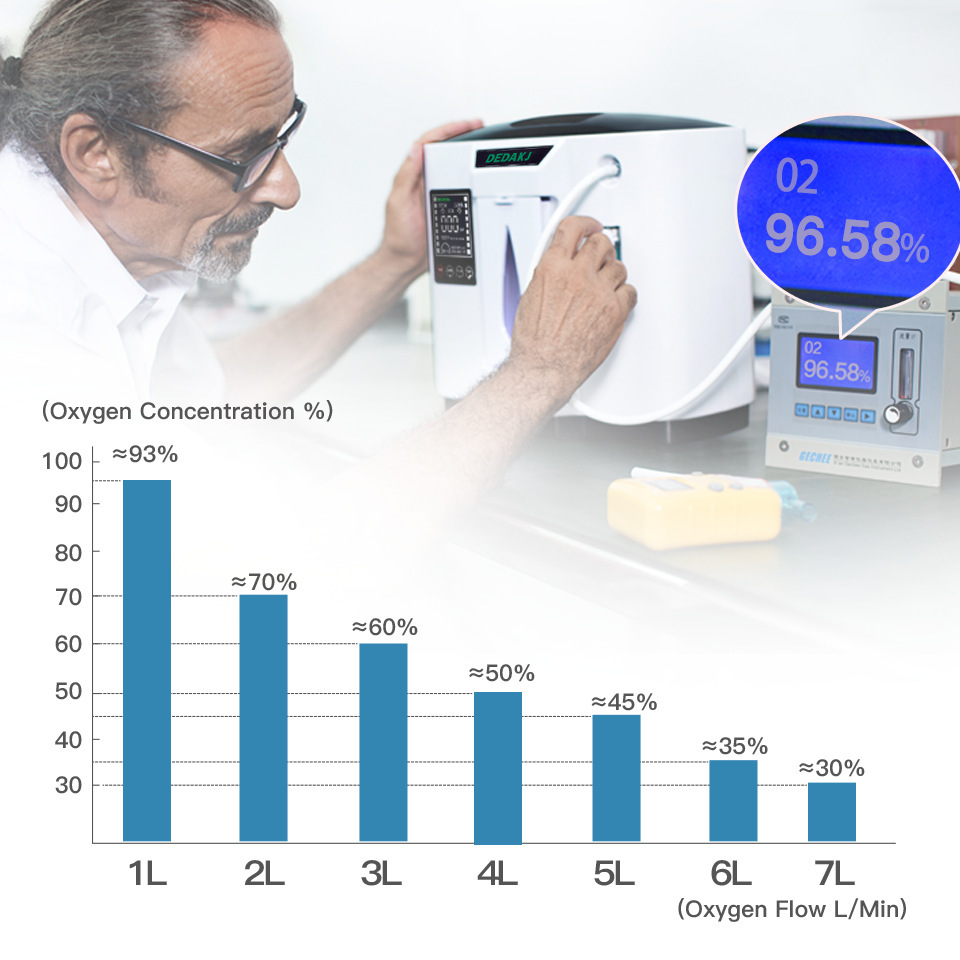

Performance of the molecular sieve: Test parameters such as oxygen concentration and flow rate to determine if the sieve is functioning properly.

Temperature changes: Excessive temperatures can reduce adsorption efficiency, so it’s crucial to monitor the working temperature of the molecular sieve.

Pressure variations: The operating pressure of the oxygen generator should stay within the designed range. Both excessively high and low pressures can affect the sieve’s performance.

Cleaning and Drying

The operating environment of molecular sieves often contains dust, oil, and water vapor, which can accumulate in the sieve’s pores and block its adsorption ability. Regular cleaning and drying are essential maintenance steps.

Cleaning: Use specialized cleaning tools to remove dust and oil from the sieve’s surface. Avoid using corrosive cleaning agents during this process.

Drying: The adsorption performance of molecular sieves is closely related to their moisture content. Excess moisture can decrease adsorption efficiency and even cause mold growth. After cleaning, the sieve should be dried. This can be done using hot air or drying equipment, but temperature control is critical to prevent damage to the sieve.

Replacing the Molecular Sieve

Over time, the adsorption capacity of molecular sieves decreases, making replacement necessary. The frequency of replacement depends on several factors, including the frequency of operation, environmental humidity, and temperature. Typically, molecular sieves have a service life of 2 to 5 years. If significant drops in adsorption capacity, clogging, or other issues occur, it’s time to replace the sieve.

When replacing the molecular sieve, follow the manufacturer’s manual to ensure the replacement process does not affect the generator’s normal operation. Select the appropriate molecular sieve based on the model of the oxygen generator and the required gas output.

Storage and Transportation

When molecular sieves are not in use, they should be stored in a dry, well-ventilated area to prevent contamination from moisture or oil. Sealing the sieves in airtight containers can help prevent moisture absorption. During transportation, protect the sieves from excessive vibration, which may damage their structure.

Preventing Contaminant Pollution

To avoid contaminating the molecular sieve during operation, it’s advisable to install appropriate filtration devices at the air intake. This is especially important in environments with high levels of oil or particulate matter in the air. High-efficiency filters can significantly extend the service life of the molecular sieve.

Common Problems and Solutions

Decreased Adsorption Capacity

If the molecular sieve’s adsorption capacity decreases, check for moisture accumulation or contaminant buildup. Cleaning and drying can resolve most of these issues. If the problem persists, it may be necessary to replace the sieve.

Clogging

Clogging is often caused by the accumulation of impurities or too small a pore size in the sieve. This can be addressed by cleaning the sieve professionally or replacing it with a more suitable model.

Excessive Temperature

If the molecular sieve operates at too high a temperature, its performance will deteriorate. In this case, check the cooling system to ensure it is functioning properly and keeping the temperature within the optimal range.

Conclusion

Maintaining and caring for molecular sieves in industrial oxygen generators is essential to ensure long-term, efficient operation of the equipment. Regular inspections, cleaning, drying, timely replacement, and proper storage can significantly extend the service life of the molecular sieve, enhance the generator’s efficiency, reduce maintenance costs, and prevent production disruptions. Whether for routine maintenance or emergency repairs, Our after-sales service is reliable. We assist businesses in developing scientific maintenance plans based on actual usage conditions to ensure oxygen generators perform at their best and guarantee safe production.

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap