After years of experiments by experts and scholars, it is found that zeolite molecular sieves have better effects when applied to oxygen production equipment. Oxygen concentrator is an industrial structure made by absorbing oxygen from the air through pressure swimming absorption technology or membrane separation method. In the PSA process (Pressure Swing Adsorption), pressurized air is passed through a series of vessels with zeolites as the absorbing membranes. They absorb the nitrogen component of the air and expel oxygen, which is packed in convenient cylinders for medical use.

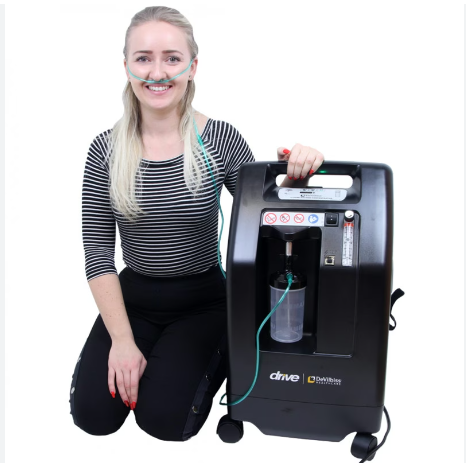

Lithium Zeolite Molecular Sieves Can Be Applied In Oxygen Production

Over the past 30 years, experts from Europe, the United States, China, and India have maturely applied this zeolite oxygen production equipment, from understanding the needs and gaps of oxygen cylinders in rural areas, from procurement to installation, guiding the operation process, paving the way for the future, and providing a full range of solutions Health services provide a long-term chain of self-sufficient and sustainable oxygen production methods for the medical and health field.

Oxygen concentrator systems based on Lithium Molecular Sieve are widely used to produce medical grade oxygen. Zeolites are used as molecular sieves, using their ability to trap impurities to generate pure oxygen from air, leaving behind highly pure oxygen and up to 5% argon in a process that involves the adsorption of nitrogen.

The PSA oxygen generator utilizes the characteristics of 13XHP Molecular Sieve's selective adsorption of nitrogen in the air and the ability of nitrogen adsorption to change with pressure changes, and achieves the purpose of continuous production of oxygen by changing the operating pressure of the adsorption bed.

The PSA oxygen generator compresses the raw air to 0.3-0.6MPa in the air compressor after filtering and dedusting, and then cools it to about 30 ℃ by the cooler, removes the free water in the compressed air, and enters the adsorber from the lower part. When the air passes through the molecular sieve adsorbent bed, the moisture, CO2 and nitrogen in the air are adsorbed by the molecular sieve, the oxygen flows out from the top of the adsorber, part of it is output as product gas, and the other part is used for cleaning and regeneration of another adsorber.

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap